SUNJ produces LV Insulation Piercing Connectors (lPCs) with Tin Covered AL Contacts

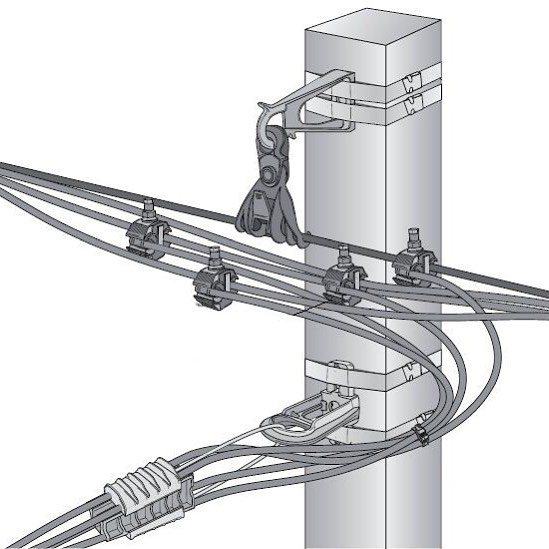

SUNJ is a direct manufacturer for Electircal Power Grids 0.4-36 KV , produce Low Voltage lnsulation piercing connectors(lPCs),which are used in LV ABC overhead cables in electrical distribution systems, it insulated piercing connectors have tined Al electrical contacts.

Here are reasons why electrical contacts are often tin-covered:

1.Corrosion resistance: Tin is known for it’s corrosion-resistant, when electacts are tin covered, they are protected from oxidation and other forms of corrosion.

For example, SUNJ insulation piercing connector’s features tined covered contacts, offer excellent corrosion resistance,ensure long-lasting performance in challenging environmental conditions.

2.Improved conductivity: Tin has a low contact resistance, which means it allows for efficient electrical conductivity between the contacts.The ZOP-57 Insulated piercing connector boasts larger cross section tined covered teeth, allowing a steady current flow and enhancing conductivity.

3.Solderability: Tin facilitates soldering and ensures reliable connections.

For lPC connectors, the tin-covered aluminum contacts not only provide good electrical conductivity but also faciitate easy soldering.

This contributes to efficient power transmission and minimizes energy loss.

4.Cost-effective: Tin is an economical metal, making it a cost-effective choice for electrical contacts, conbinated with Aluminum to use for CU conductors, it is notably cheaper than copper.

SUNJ’s insulation driling connectors utilize tin-covered AL contacts, let the lPC can be used for both Al and CU conductors,but price is more competitive than lPCs with copper contacts.